Опис

Лиття під тиском - цеmanufacturingпроцес виготовлення деталей шляхом впорскування розплавленого матеріалу вцвіль. Plastic Ін'єкція Molding is one of the most frequently used manufacturing

processes for creating plastic parts. Thanks to its high-precision,

repeatability, and cost efficiency at scale, plastic injection molding is used for

a variety of products and parts from the smallest insert up to large automotive

& aerospace parts.

The plastic injection molding process requires an injection molding

machine, raw plastic material, and a machined mold. The raw plastic material is

first melted in the injection unit and is then injected into the mold, where it

cools and solidifies into the final plastic part.

The key steps in the injection molding process include:

-Затискання

The two sides

of the mold are closed and clamped shut.

-Ін'єкція

Матеріал подається в машину і штовхається до форми. Поки це відбувається, матеріал плавиться під дією тепла та тиску. Потім пластик впорскується у форму, цей процес називається «Постріл».

-Cooling

Пластик у прес-формі охолоджується і застигає у формі деталі.

-Викид

Після переохолодження воно викидається із форми.

Auwell offers 2 business models to meet the needs of the client for

plastic injection molding projects. Namely supply tooling only models or, final

products models.

-Моделі лише для оснащення

For this business model,

Auwell offers the tooling design based on the product design and machine data

for client confirmation, the details include tooling structure, lifetime,

tooling material, hardness, etc. Clients may provide completed tooling designs

for production. For this tooling only option, for standard parts, we will use the

most common with globally recognized one for easy maintenance. In general, this

option is preferred for large size and high-volume products, Plastic

Ін'єкція Tooling Автомобільна is a typical catalogue for this business

model.

-Моделі кінцевих продуктів

For this business model, Auwell is responsible for the plastic injection molding parts, and to meet the client’s specifications. The type of injection machine and tooling structure/design used is decided by our team. For this business model, once the client pays the tooling cost, Auwell will be responsible for tooling maintenance and replacement for the entire product lifetime. This model is preferred for small sizes and precise plastic injection molding parts. Please refer to “Plastic Ін'єкція Partsâ € розділ для більш докладної інформації.

Another key difference of the two-business model is, for “Tooling Only

Model”, the mold cost is considerable higher than “Final Products Model” as for

“Final Products Model”, Auwell does not make any margin from the tooling

development. For “Final Products Model”, if the clients want to take the mold

or, shift to another supplier, it is not guaranteed that the mold works

properly at another machine at another manufacture, and, a certain proportion

of mold development cost will be charged before mold transferring.

Apart from plastic injection molding, we also provide the following

services:

-Rapid 3D printed prototypes

-Надлиття

-Insert molding

-Термоформування

-Rubber & Silicone

Molding

Технічні характеристики

-Матеріал

Following plastic

material available for our plastic injection molding services:

Ø PA 6/6 | Поліамід 6/6, Нейлон 6/6

Ø ПАРА | Поліариламід

Ø PBT | Polybutylene Terephthalate, Valox

Ø PBT-PET | Полібутилентерефталат-Поліетилентерефталат

Ø ПК | Полікарбонат

Ø PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene

Ø ПК-PBT | Полікарбонат-полібутилентерефталат, Xenoy

Ø ПК-ПЕТ | Полікарбонат-поліетилентерефталат

Ø РСТ | Поліциклогексилендиметилентерефталат

Ø PE | Поліетилен

Ø PE-PP | Поліетилен-Поліпропілен

Ø PE-PS | Поліетилен-Полістирол

Ø PEBA | Polyether Block Amide

Ø PEEK | Polyether Ether Ketone

Ø PEI | Polyetherimide, Ultem

Ø PES | Polyether Sulfone

Ø PET | Polyethylene Terephthalate, Rynite

Ø PLA | Polylactic Acid

Ø PMMA | Polymethyl Methacrylate, Acrylic

Ø POM | Acetal Polyoxymethylene, Delrin

Ø ПП | Поліпропілен

Ø PPA | Polyphthalamide

Ø PPS | Поліфеніленсульфід, Райтон

Ø PS | Полістирол

Ø PS-PPE | Полістирол-поліфенілові ефіри, норил

Ø БП | Полісульфон, Удель

Ø ПВХ | Полівінілхлорид (Шор D)

Ø PVDF | Polyvinylidene Fluoride

Ø SAN | Styrene Acrylonitrile

Ø TPO | Thermoplastic Polyolefin

Ø TPU | Thermoplastic Polyurethane (Shore D)

Ø Замовлена на замовлення смола

-Moldbase

LKM, HASCO, 1.1730, S50C, S55C, 1050, 1055

-Активні елементи

Ø P20, 1.2311, 1.2312, 1.2738, 1.2343, 1.2344, H11, H13, 420

Ø ASSAB: 718, 718S, 718H, S316 / S316H / S316 SUP / S316H SUP, POLMAX / 168

Ø SAARSTAHL: GS738, GS2311, GS2312, GS638, GS688, GS2316

Ø DAIDO: NAK80, NAK55, PX88, PX4, PX5, S-Star (A)

Ø BOHLER: M201, M202, M238, M300 ESR, M310 ESR, M310H ESR

-Hotrunner

YUDO, INCOE

-Поверхня цвілі

Photo etching, erode

structure, shot blaster, line polishing, high gross polishing, mirror

Polishing.

-Машини: 100-3000 тонн сила закриття

Переваги

-Багатий досвід

More than 20 years of

experience in plastic injection molding tooling development and part production,

especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Швидкий оборот

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to provide fast prototypes in 3

working days, for simple and small size tooling, we are able to deliver first

sample in 4 weeks.

-Комплексний постачальник рішень

Auwell provides

comprehensive services for plastic injection molding projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-Жорстка політика контролю якості

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Матеріал certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Гнучкий термін оплати

For tooling, the general

payment term is 50%-40%-10%, meant 50% deposit, 40% after first sample free and

10% 2 weeks after client receive tooling or first batch product delivery. For

mass production, we offer flexible payment terms, reasonable credit terms will

be given, the client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

Програми

-Plastic injection molding

products have widely been used in almost all industrial sectors

including:

-Аерокосмічна та оборонна

-Автомобільна

-Agriculture Machinery

-Energy

-Electronics

-Construction

-Transportation

-Промислові

-Consumer Products

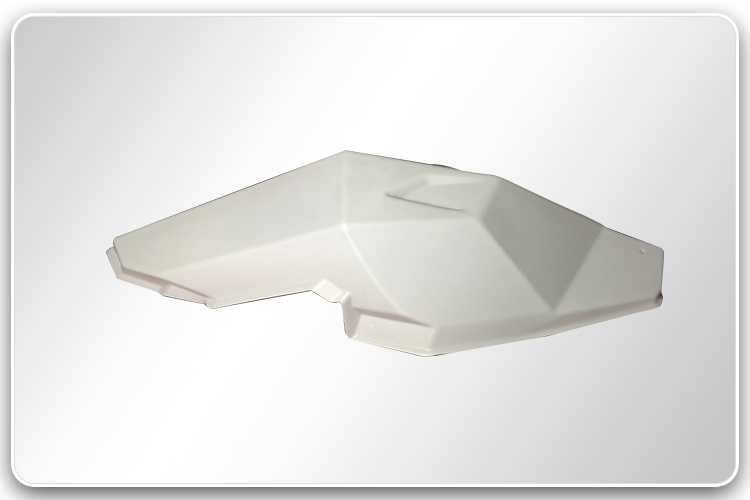

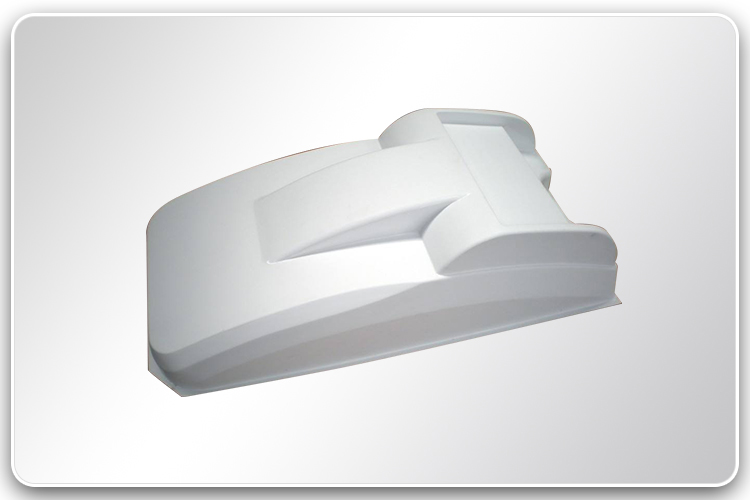

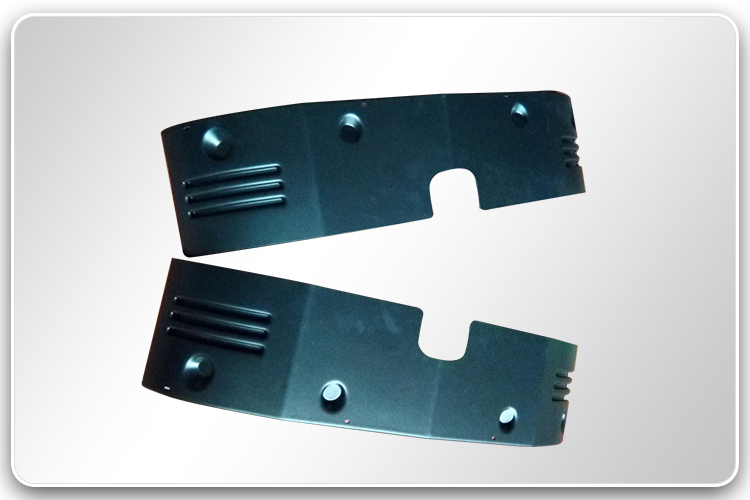

Наступні каталоги виробів для лиття пластмас під тиском - це ті, які Auwell виготовив та поставив нашим видатним світовим клієнтам. Будь ласка, клацніть відповідні фотографії для деталей. Будь ласка, зауважте: більшість продуктів призначені лише для демонстрації.

Plastic Ін'єкція Mold for Автомобільна Parts

Plastic Ін'єкція Mold for Автомобільна Parts

Plastic Ін'єкція Parts

Plastic Ін'єкція Parts

Plastic Ін'єкція Надлиття

Plastic Ін'єкція Надлиття

Plastic Термоформування Parts

Plastic Термоформування Parts

Гумово-силіконові лиття

Гумово-силіконові лиття

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик